![]()

Concrete Waterproofing

Concrete is one of the strongest, most cost-effective construction materials in use today. When combined with steel reinforcement, the structure achieves the tensile and compressive strength to form a wide variety of long-lasting structures. These two materials work very well together due to the combined strength and similar thermal expansion properties. However, these structures are not maintenance-free and need to be protected in order to maintain their structural integrity. This is where concrete waterproofing becomes important.

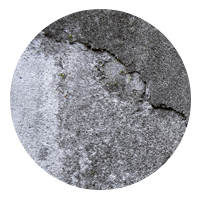

There are several items that can affect the structural integrity. In our climate, the most common ones are chloride contamination, water contamination, and freeze/thaw damage. Concrete is porous, like a sponge, and left unprotected will allow water and chloride contaminants to penetrate over time. Left untreated, these contaminants will reach the steel reinforcements and begin to deteriorate the steel, causing major defects in the integrity of the structure.

Here is quick overview of the most common failures we see in our climate:

Freeze/Thaw Damage: This occurs when water penetrates the surface of the concrete into cracks, pores and capillaries. When this water freezes, it expands and breaks apart the concrete. During each cycle, the problem accelerates. As the damage increases, the steel reinforcement underneath becomes more vulnerable to contaminants.

Water Contamination: Water will penetrate untreated concrete. When it reaches the steel reinforcement, the steel begins to rust. Once the rust starts, it doesn't stop and the only way to prevent extensive damage is to remove the concrete and repair the steel reinforcement.

Chloride Contamination: De-icing agents in our climate are the largest source of chloride for parking facilities. The chloride mixes with water and penetrates untreated concrete. When chloride reaches the steel reinforcement, it accelerates the deterioration of the steel.

Preventing Concrete Damage

The best way to prevent damage is to prevent penetration into the concrete. A waterproof barrier is the best method of prevention. This has been recognized by other countries in our climate zone as well and is even a required component in new construction to meet building codes in Canada. Applying a waterproof coating is a small fraction of the cost of an extensive repair. As the old adage goes, an ounce of prevention is worth a pound of cure.

Concrete Waterproofing Is The Best Solution

At Wahlen Works, we are always exploring better solutions to problems that our customers face. We look for the latest technology for all of our services. This is why we have decided to partner with Alchemco and to offer their TechCrete 2500 waterproofing system to our customers. The 2500 Waterproofing system is an innovative, long term, minimal maintenance solution to create a waterproof barrier inside of the concrete.

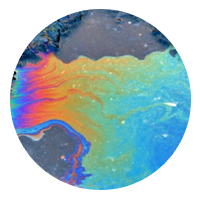

TechCrete 2500 is not a membrane. Rather, it is a penetrating solution that reacts with calcium and water to form a calcium silicate gel that fills cracks, pores and capillaries. The gel expands, filling cracks up to 2mm wide.

TechCrete 2500 is a sub-surface barrier. It cannot be peeled, chipped, or scraped away. It doesn't alter the appearance of the concrete or discolor over time like membranes do. If you do want an aesthetic upgrade, we can also install Alchemco’s ChoiceCote on top of the waterproofing system to create an aesthetically pleasing, long term waterproof barrier.

TechCrete 2500 Increases The Durability Of The Structure

The TechCrete 2500 Waterproofing System enhances the durability & sustainability of the structure. The benefit to you, the owner, is that your structure lasts longer and produces revenue for you over a longer period of time. TechCrete densifies the surface of the concrete, increasing its ability to withstand pedestrian and vehicular traffic.

One of the best features of TechCrete 2500 is its longevity. It stays active beneath the surface and will continue to seal future stress cracks that form—up to .04mm wide. This creates a “self-healing” effect in the concrete. Since it stays active, we are able to offer a warranty ranging from 15-30 years depending on the age and condition of the facility. Yes, 15+ years! If the system fails, and the failure is not a result of a structural defect of the structure, Alchemco will back their product with a material and labor warranty for re-installation.

Techcrete 2500 is also trafficable between installation phases. There is no need to shut down your facility for an extended period of time during install. We can install the system during off-hours and keep the inconvenience of closed areas to a minimum, also keeping lost revenue to a minimum. In addition, is very easy and inexpensive to maintain. The only requirements are regular cleaning and annual pressure washing, which we can provide.

TechCrete 2500 Contains No VOCs

TechCrete 2500 is environmentally-friendly, with no volatile organic compounds (VOCs). It is safe to use for protecting drinking water containment vessels and if the concrete structure is ever torn down, the concrete remains recyclable.

By choosing Wahlen Works to install your waterproof barrier, you can be assured of a quality installation. We work directly with Alchemco to ensure the correct products are chosen and the installation is up to standards. We stand behind our work as we have for nearly 50 years.